Production

In our production, you can order tools for any sawmills. We use European technologies and professional equipment in the production and restoration of tools, which allows us to obtain a tool of the highest quality. 43 pieces of equipment are involved in the production process, which serves 24 people. Our employees are motivated to constantly develop and move forward, we are constantly improving our skills and knowledge.

What stages of production does a band saw go through?

Choosing a band saw blade: an important parameter of a band saw is the width of the blade, they are divided into 2 types: narrow (up to 50 mm) and wide (from 80 mm). We use Japanese SK-5 steel canvas, Germany steel canvas of C75S brand, 51CrV4, D6A and German canvas of CR-200 Extra brand. The canvases are offered in increments of 35 and 45 mm.

Choosing a band saw blade: an important parameter of a band saw is the width of the blade, they are divided into 2 types: narrow (up to 50 mm) and wide (from 80 mm). We use Japanese SK-5 steel canvas, Germany steel canvas of C75S brand, 51CrV4, D6A and German canvas of CR-200 Extra brand. The canvases are offered in increments of 35 and 45 mm. Rolling of the saw blade. A common and necessary operation for all types of wide saws is their rolling, which ensures, first of all, the plasticity of its web, and this is the proper fit of the pulley of the band saw machine.

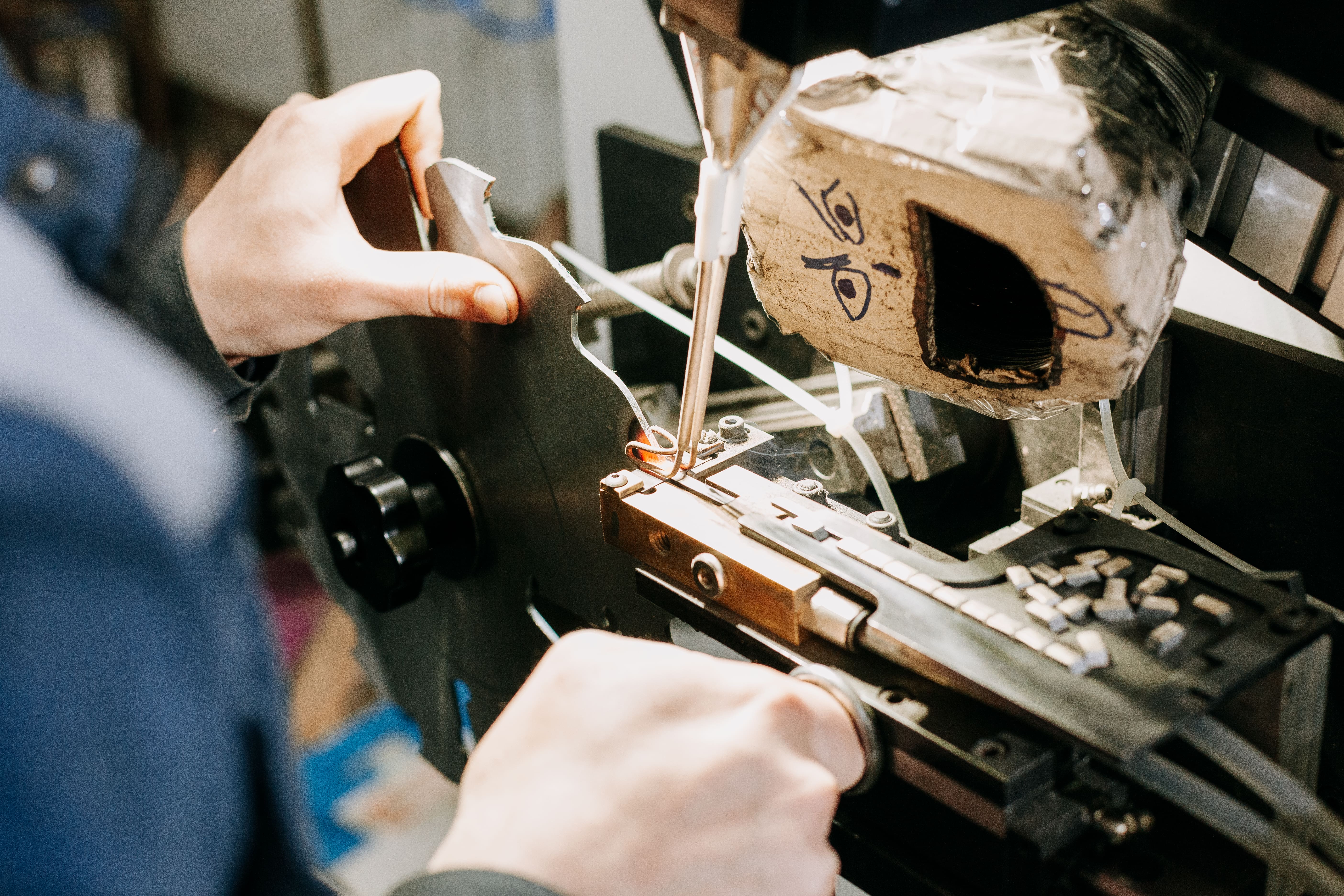

Rolling of the saw blade. A common and necessary operation for all types of wide saws is their rolling, which ensures, first of all, the plasticity of its web, and this is the proper fit of the pulley of the band saw machine. The stage of stellitization. This is applied by surfacing a tooth of increased hardness on the saw body. Cobalt-based alloys are used as the deposited metal. Saws equipped with stellite are especially effective when processing raw and frozen wood. They allow you to file up to 50 m3 without overfilling.

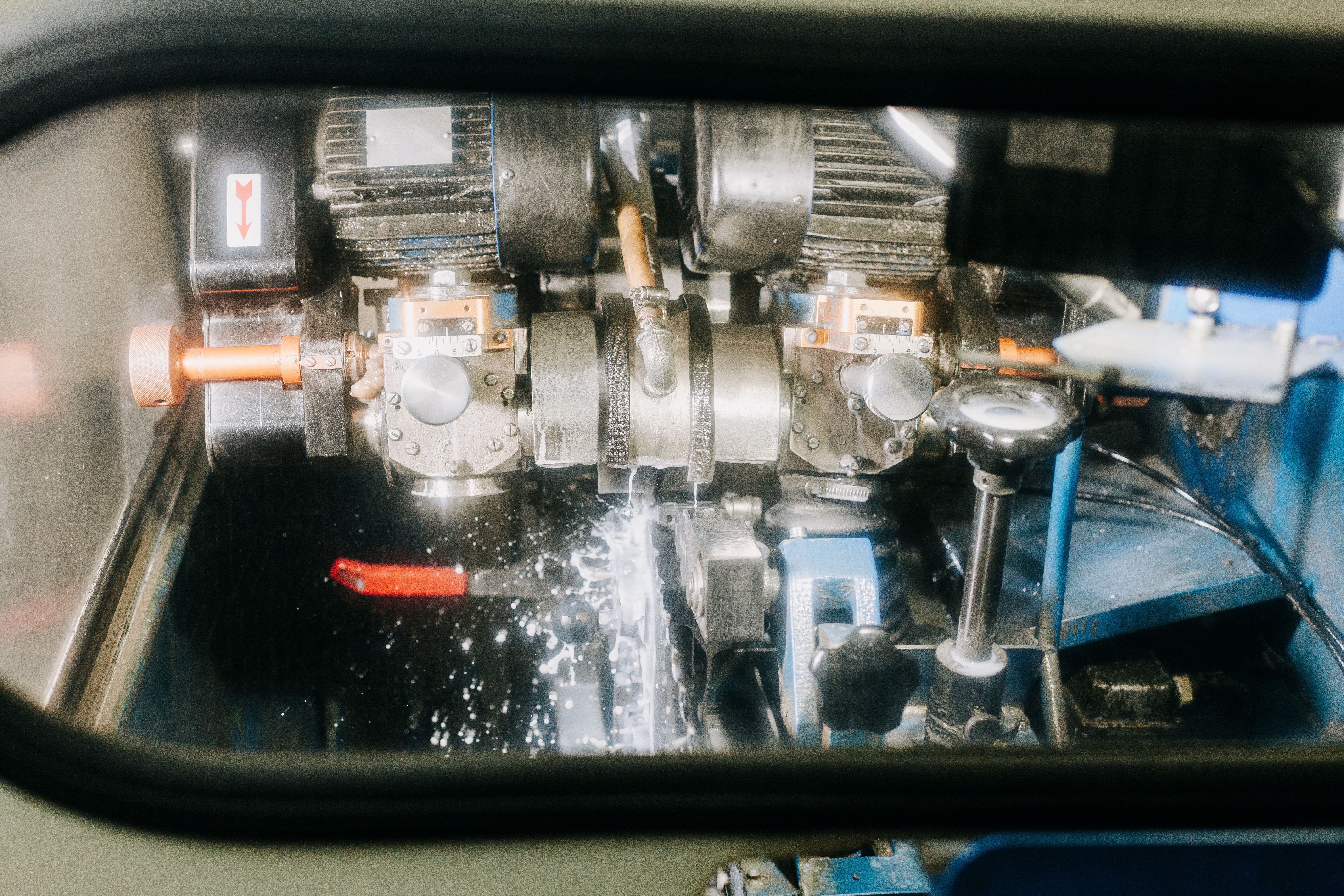

The stage of stellitization. This is applied by surfacing a tooth of increased hardness on the saw body. Cobalt-based alloys are used as the deposited metal. Saws equipped with stellite are especially effective when processing raw and frozen wood. They allow you to file up to 50 m3 without overfilling. Sharpening the tooth. Tooth sharpening is performed on three sides using a diamond tool. We also provide the option of sharpening "Wolf's tooth" for sawing frozen wood.

Sharpening the tooth. Tooth sharpening is performed on three sides using a diamond tool. We also provide the option of sharpening "Wolf's tooth" for sawing frozen wood. Quality control: All saws undergo output quality control of the weld and overhang teeth.

Quality control: All saws undergo output quality control of the weld and overhang teeth. Packing and shipping: a protective tape is put on the saw teeth, protecting the saw teeth during transportation, as well as preventing cuts on the teeth.

Packing and shipping: a protective tape is put on the saw teeth, protecting the saw teeth during transportation, as well as preventing cuts on the teeth.

We deliver orders by our own transport and transport companies in Belarus and Russia.

We deliver orders by our own transport and transport companies in Belarus and Russia.